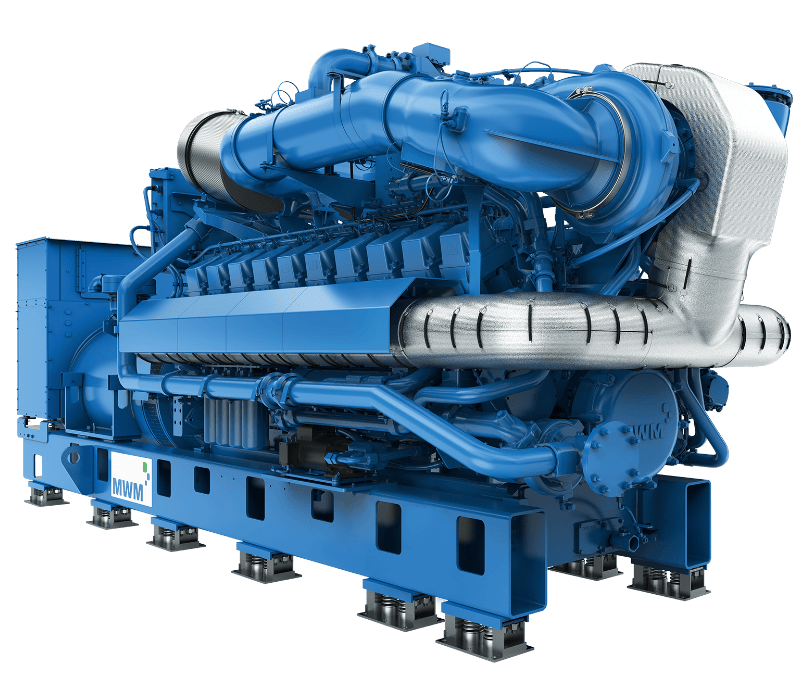

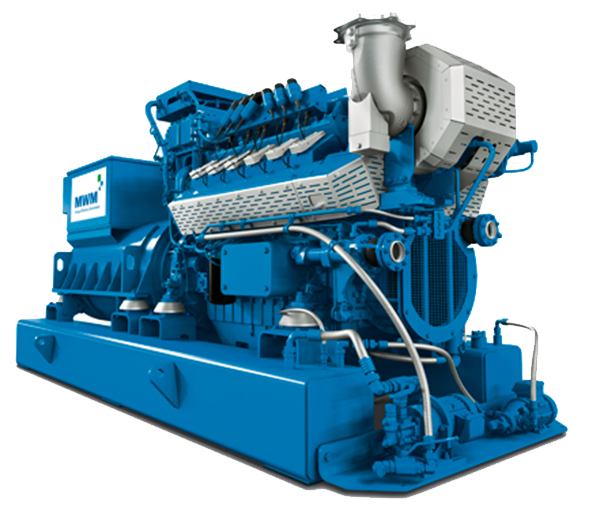

TCG 4170

Gas Engine TCG 4170

2,500 kWel

Made to perform. Achieve your energy goals even faster and more cost-effectively—whether in grid-parallel or island-mode operation, under difficult installation conditions, changing load requirements, or high ambient temperatures.

- Output: 2,500 kWel

- Excellent electrical efficiency of up to 46 percent at optimal CHP output

- Full power in under five minutes and maximum load step performance of 60 percent

- New TCS control system available in various configurations

- Location-independent 24/7 digital plant monitoring

- High fuel flexibility, designed for natural gas, propane gas, hydrogen blends, and other types of gas

- Currently available as 50-Hz variant (60-Hz variant will be available in 2026)

MWM TCG 4170 Gas Engine: The Smart Choice.

Robust, Smart, Highly Efficient.

- Output: 2,500 kWel

- Cutting-edge electrical efficiency of up to 46 percent

- Flexible use for various applications and gas types, such as natural gas, propane gas, hydrogen blends, and other gases

- New TCS control system available in various configurations and as customized solutions

- Fast ramp-up and full power in less than five minutes

- Full power at intake air temperatures of up to 45 °C

- High robustness thanks to proven components, for maximum reliability

- Low lifecycle costs thanks to reduced maintenance times and long service intervals

- Easy maintenance and low oil consumption of ≤ 0.122 g/kWh

On This Page

Description – MWM TCG 4170 V20 gas engine

TCS Control System for CHP Plants in Various Configurations

Real-Time Digital Plant Monitoring with VisionLink®

Performance data – TCG 4170 V20

Technical data and service intervals – TCG 4170 V20

TCG 4170 V20 brochure

The MWM TCG 4170 V20 gas engine is optimized for high flexibility and sets new standards in electrical efficiency. The High Response configuration (TCG 4170 V20 R) delivers an outstanding efficiency of up to 46 percent in the 50 Hz version.

TCG 4170 V20: Generator Set for Utility Providers, IPPs, and Critical Infrastructure

The MWM TCG 4170 V20 generator set combines high electrical efficiency with flexible operation. Thanks to its electrical efficiency of up to 46 percent, the engine is ideal for grid-parallel or island-mode operation and primary power supply. Utilities, independent power producers (IPPs), critical infrastructure, refineries, and petrochemical companies in particular benefit from the flexible operation and outstanding efficiency of the TCG 4170 V20.

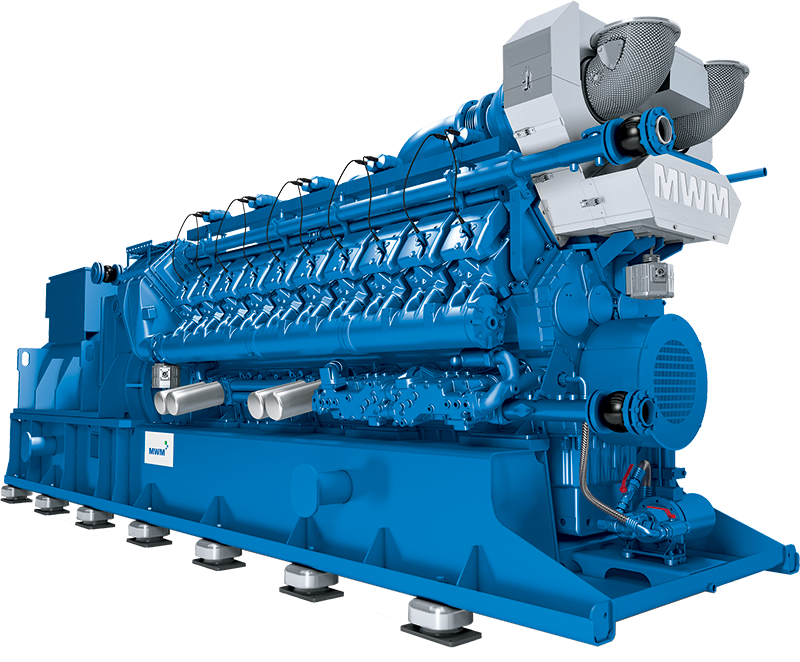

High Load Switching for Energy-Critical Industries and Segments

The TCG 4170 V20 offers fast ramp-up and full power in less than five minutes. This high degree of operational flexibility makes the engine ideal for deployment in industries that require short response times, such as petrochemicals, refineries, mining and metallurgy, production facilities, and data centers.

Consistent Output under Demanding Operating Conditions

The air filter design, which has been specially adapted to the TCG 4170 V20, allows intake air temperatures of up to 45 °C at full power. The robustness of the generator set ensures reliable operation even in regions with high ambient temperatures. This saves costs, space, and energy for complex cooling and ventilation systems, which is particularly advantageous for containerized plants.

Description – MWM TCG 4170 V20 Gas Engine

Maximum Electrical Efficiency and Flexibility

- The TCG 4170 V20 R impresses with its high electrical efficiency of up to 46 percent.

- With an electrical power range of 2,500 kW (up to 2,536 kW with natural gas), the engine is suitable for energy generation in companies in various industries.

- The overall efficiency of the TCG 4170 V20 is 89.1 percent or even up to 89.6 percent when the engine coolant temperature is 88 °C.

- 100 percent output in two steps and intake air temperatures of up to 45 °C make the TCG 4170 V20 ideal for demanding locations.

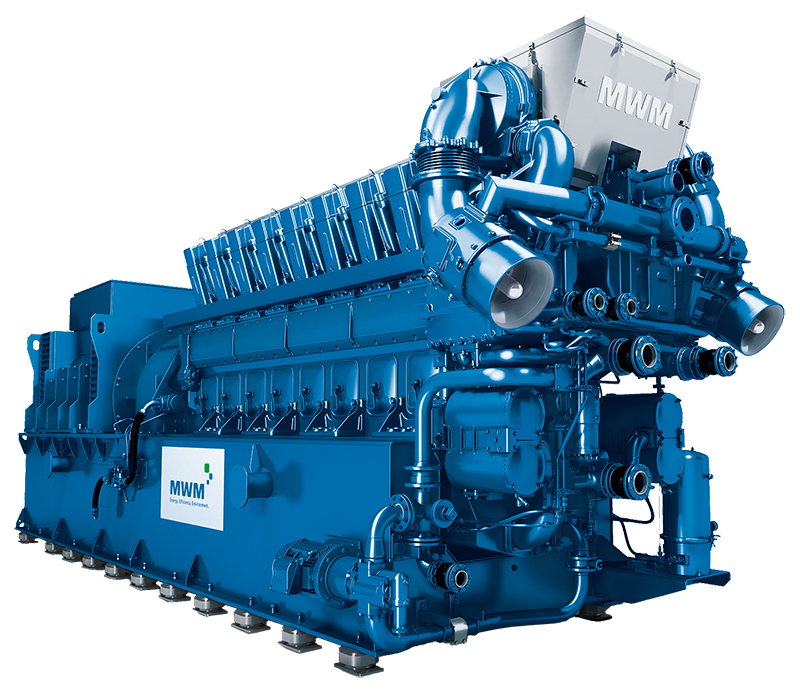

Optimum Efficiency and Profitability

- High profitability: The low operating costs of the TCG 4170 V20 reduce the total cost of ownership.

- Real-time monitoring with VisionLink® and the TCS control system ensure optimum plant management.

- Maintenance-friendly design with up to 80,000 operating hours until the next general overhaul (if the gas quality is high)

- TCG 4170 V20 spark plug service life 5,000 to 10,000 hours

- 2,000 hours until the next oil change interval (4,000 hours with synthetic oil)

- Low lifecycle costs and low oil consumption of ≤ 0.122 g/kWh

Suitable for Numerous Gas Types and Applications

- Maximum operating efficiency and high fuel flexibility, designed for natural gas, propane gas, hydrogen blends, and other types of gas

- Ideal for reliable power generation in numerous industries and segments, including utilities, independent power producers (IPPs), critical infrastructure, food processing, greenhouse facilities, data centers, refineries and petrochemical plants, mining and metallurgical plants, and manufacturing facilities.

- The TCG 4170 V20 is available as 50-Hz variant (60 Hz available in 2026)

TCS Control System for CHP Plants in Various Configurations

The new TCS control system for CHP plants is available in various configurations and as a customized solution. The system is available in configurations such as TCS 100 (single genset controller) and TCS 200 (genset paralleling controller). Additional configurations are available on request. The TCS control system combines all important power plant data in a well-structured way in a single system. The entire energy generation plant is controlled securely and reliably via the TCS control system, ensuring that operators always have optimum access to their plant and all relevant data.

Real-Time Digital Plant Monitoring with VisionLink®

With the help of the digital application VisionLink®, CHP plants can be monitored in real time from anywhere. Operators can use the system to identify potential problems at an early stage and respond proactively before a potential plant outage occurs. VisionLink® allows you to keep track of your plant data, plan maintenance measures more effectively, and coordinate operations and support processes in the best way possible. The fleet management system is designed to process large amounts of data and is equipped with multi-layer security controls and safeguards to prevent unauthorized access.

Performance Data – TCG 4170 V20

Natural gas applications, NOx ≤ 500 mg/Nm3*

| Type | TCG 4170 V20 50 Hz R = High Response | |

|---|---|---|

| Electrical output | kW | 2,536 |

| Electrical efficiency | % | Up to 46.0 |

| Thermal efficiency ** | % | 43.1 |

| Total efficiency | % | 89.1 |

| Power-to-heat ratio ** | 1.07 | |

* At 5 percent O2 and dry exhaust gas, according to ISO 8528-1 at U = 0.4 kV, cos phi = 1.0 at 50 Hz, methane number of MN 80. Exhaust gas cooled to 120 °C.

** According to ISO 3046-1

*** The power-to-heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

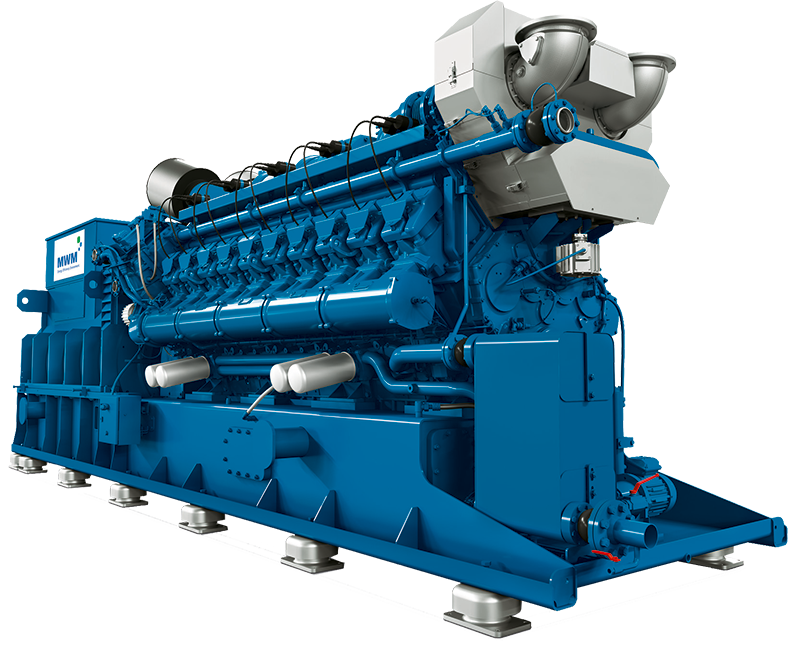

Specifications and Service Intervals – TCG 4170 V20

Dimensions and weights

| Type | TCG 4170 V20 50 Hz | |

|---|---|---|

| Bore/stroke | mm | 170 |

| Displacement | dm3 | 97.6 |

| Speed | min-1 | 1,500 |

| Length | mm | 6,383 |

| Width | mm | 2,482 |

| Height | mm | 2,534 |

| Dry weight genset | kg | 20,500 |

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Brochure – MWM TCG 4170 V20 Gas Engine

Here you can find further information on the TCG 4170 V20 generator set.

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

Gas engines & Products

Gas Engine TCG 2020

Best electrical and thermal efficiency in its class. All gas types: natural gas, biogas, mine gas, landfill gas, sewage gas.

Gas Engine TCG 2032

High reliability. Low operating costs. Gas types: natural gas, landfill gas, sewage gas, mine gas, coke oven gas. Mainly used in large IPP projects with up to 100 MWel.

Gas Engine TCG 3016

New development – greatly reduced operating and installation costs and fully digitized power plant control.

Gas Engine TCG 3020

The All-Round Talent. Smart, secure plant control. Higher output and profitability despite compact design.

MWM TCS Control System

The MWM TCS control system offers efficient and practical control and monitoring of individual generator sets, energy plants, and microgrids.

Video Clip: Unveiling of the TCG 4170 V20 Generator Set at the MWM Energy Days 2025

* By clicking the link, you will leave this MWM website and access the online presence of another provider. There, the respective provider’s privacy policy applies, and cookies may be set by the provider. We do not have any influence on this.