Newly Developed TCG 3016 Gas Engine – Efficiency Goes Digital

Newly developed TCG 3016 gas engine – efficiency goes digital

Newly developed TCG 3016 gas engine – efficiency goes digital Industry 4.0 or “Efficiency Goes Digital”

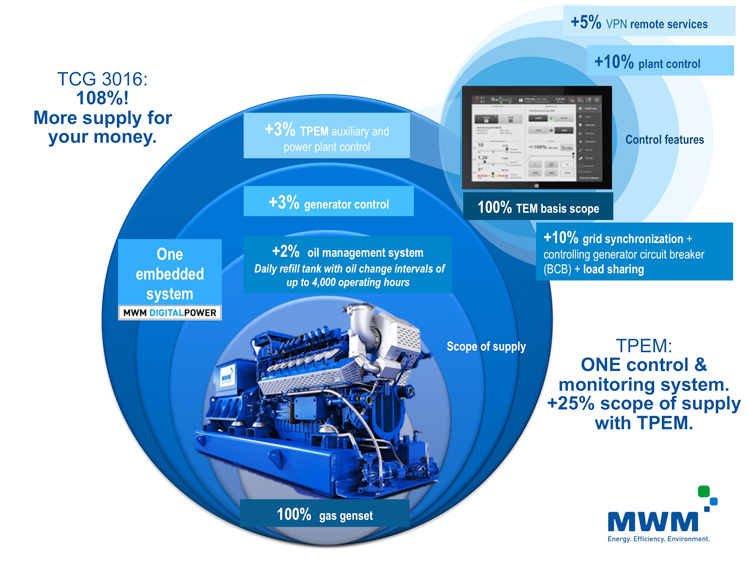

Along with the TCG 3016, MWM will also introduce the full integrated digital power plant control TPEM. Apart from controlling the genset, this system enables optimum control and monitoring of the entire energy generation plant. Modern energy generation plants are characterized by complex applications and custom circuitry. Automation and closed-loop control with maximum operating security and seamless communication play a key role, which TPEM effectively handles. In this way, additional controls are no longer necessary, and optimum control of the energy generation by the gas power plant is ensured. TPEM is unique in terms of its proximity to the hardware – after all, who is more qualified to develop and optimize software for the gas engine and the genset than the manufacturer himself? The system, which can be customized to customer needs and the individual application case, will replace the TEM control system in all future MWM series to deliver improved efficiency and flexibility.

High Efficiency, Low Operating, Installation, and Building Costs

The greatly reduced cost of installation of the gas engines and of the operation of the entire energy generation plant represents one of the greatest benefits of the new TCG 3016 gas engine. As the oil tanks of the new gas engines of the TCG 3016 series are integrated in the genset and do not need to be planned and installed separately, the installation costs are lower, and the required setup area is smaller. Moreover, the TCG 3016’s generator is firmly flanged to the gas engine. As the vibration decoupling takes place directly between the components and the base frame, the setup costs for the fundament are lower than for other gas engines. The greatly reduced oil consumption of <0.1 g/kWhel and the resulting longer oil change intervals also represent an important factor that saves servicing costs. The TCG 3016 genset is robust and highly efficient. This is evident from the unique combination of long maintenance intervals of up to 80,000 operating hours and an electrical efficiency of up to 43.5 percent.

Further Information

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com