MWM Remote Asset Monitoring (RAM)

Digital and Efficient

Everything under control: More transparency and value for CHP plants with MWM Remote Asset Monitoring

- Prevent costly shutdowns

- Reduce total costs of ownership

- Increase availability

- Improve operating performance

MWM Remote Asset Monitoring (RAM) for CHP Plants

Efficiency Goes Digital.

- 24/7 digital monitoring of your cogeneration/trigeneration plant

- Improved planning of scheduled downtime

- Positive impact on profitability, efficiency, and operating costs

- Comprehensive data analysis functions

- Notification via push messages in the event of alerts, warnings, and malfunctions

- Better estimation of repair and maintenance costs

- Multi-layer security controls and safeguards to protect the system against unauthorized access

- Maximized availability of your cogeneration/trigeneration plant

With the digital condition monitoring application MWM Remote Asset Monitoring (RAM), you can monitor your systems in real time from any location worldwide. It allows you to proactively react to any issues on site. By using MWM RAM, potential damage can be identified at an early stage before it causes a shutdown of your engine CHP plant. The early detection helps you to save repair costs and resume operation faster.

On this page

Video: MWM Remote Asset Monitoring

What is MWM Remote Asset Monitoring (RAM)?

What does MWM RAM offer users?

Technical benefits of MWM RAM at a glance

MWM RAM with TPEM Integration

Video: MWM Remote Asset Monitoring

PRIVACY NOTE: If you play a video, privacy regulations of YouTube apply.

All language versions of the video on YouTube: EN

Download Video: EN

(2.5 minutes, HD, 302 MB, MP4)

What is MWM Remote Asset Monitoring (RAM)?

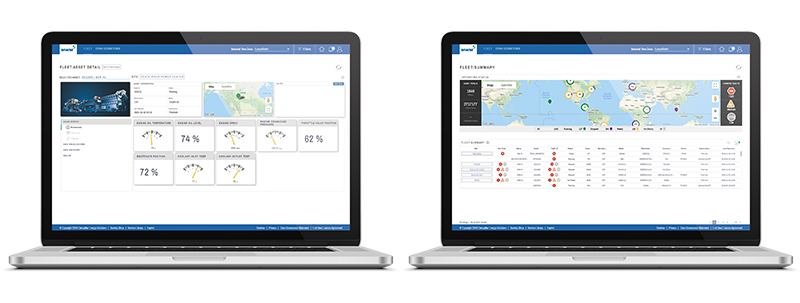

MWM Remote Asset Monitoring (RAM) is an online condition monitoring system that has been optimized for MWM CHP plants. This system assists you in keeping track of your site data and allows you to deeply analyze it.

MWM RAM facilitates the scheduling of maintenance activities and the coordination of support processes,. It is designed to process large amounts to data of complex systems such as cogeneration power plants. The use of MWM RAM also enables the early identification of potential damage and malfunction of systems such the gas engine before they cause expensive site shutdowns.

All data can be streamed either via cellular connection or through the local network. The technology is shielded by multi-layer security controls and safeguards to prevent unauthorized access or disclosure.

What Does MWM RAM Offer Users?

- More efficient operational workflows

- Optimized maintenance and servicing of the gas engine

- No separate condition monitoring system and no special IT architecture required

Higher Plant Performance

- Supports higher availability of your cogeneration/trigeneration plant

- Reduction and/or better schedulability of downtime

- Improved dispatching of technicians

Reduced Risk

- Early detection of operating issues and malfunctions of the gas engine

- Automatic notification in the event of alerts

Increased Customer Satisfaction

- Proactive customer approach

- Proactive solution offering for the customer

More Transparency

- Up-to-date information on the historical performance of the gas engine and of the entire site including peripherals

Push Notifications

- Notifications in the event of unforeseen problems and issues

Technical Benefits of MWM RAM at a Glance

- Customizable event notifications (e.g. alerts, warnings, threshold violations, site stop, etc.)

- Historical time series

- Alerts, warnings, error messages

- Automatic generation of reports (e.g. output, operating hours)

- Map view of the entire fleet (including traffic light view for alerts, warnings, notifications)

- Push notifications

- Unlimited number of users

- Access to 13 months of historical data via user interface

- Suitable for all gas types and gas applications

MWM RAM with TPEM Integration

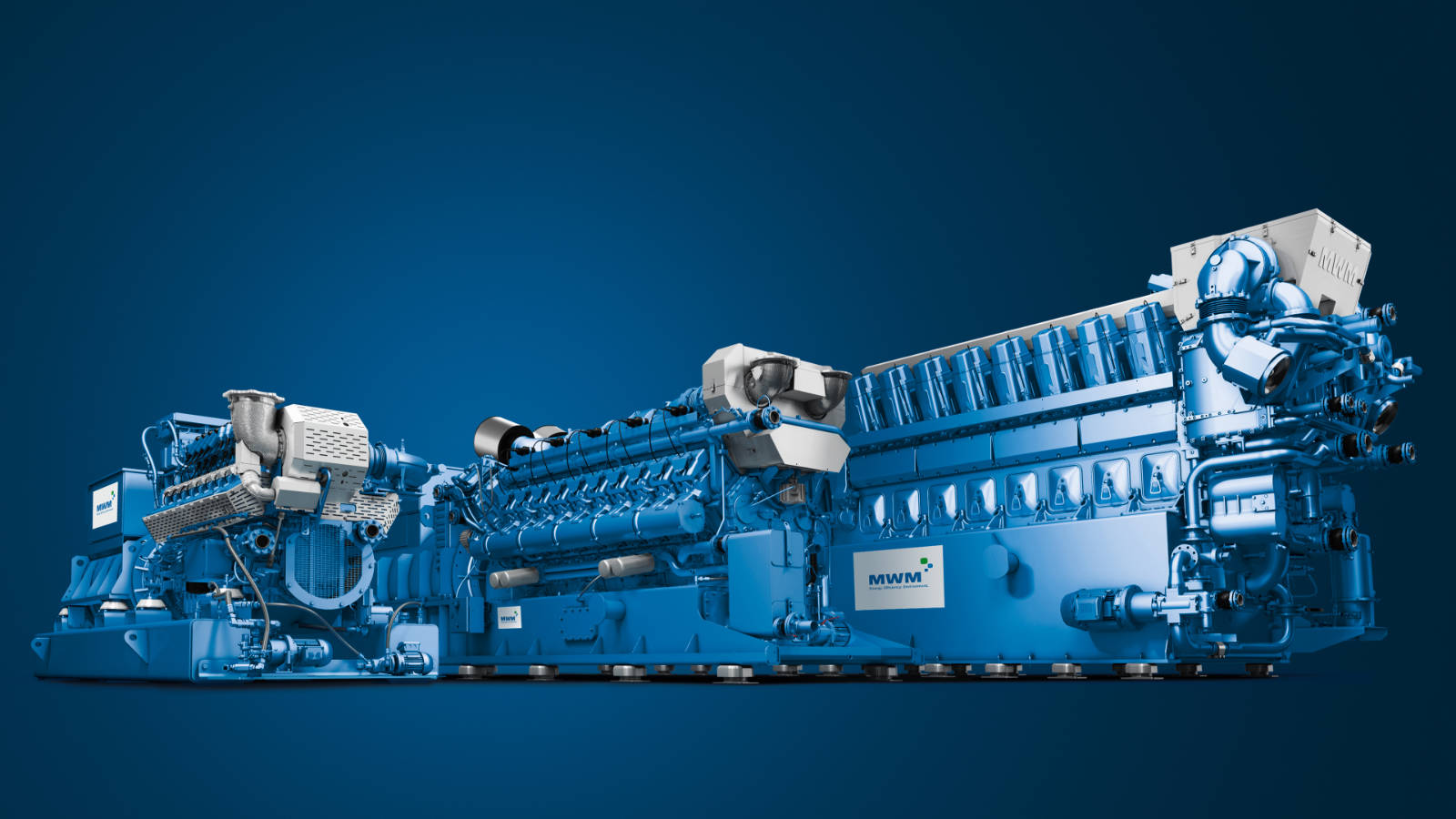

MWM RAM (Remote Asset Monitoring) is available for MWM gas engines with the digital power plant control TPEM (Total Plant & Energy Management). New gas engines can be delivered RAM-ready with TPEM CC Factory Fit. Existing plants can easily be upgraded with a retrofit kit.

RAM and TPEM – Your Benefits

- Optimum troubleshooting support through instant messages and reports

- Easy support of multiple gas engines and entire fleets

- No need for installation, additional hardware, or wiring

- Always secure and up to date thanks to online updates

- Use of existing TPEM Ethernet connection

- Cellular connection possible

- Easy end-to-end communication

TPEM CC Factory Fit and Retrofit Kits for Your Plant

MWM gas engines are delivered RAM-ready, equipped with TPEM CC Factory Fit. By default, TPEM CC comes with a PLE telematics device. As it is fully integrated in the TPEM cabinet, no further wiring is required. The TPEM Ethernet connection is part of the standard features; a cellular module is available on request. The easy online activation of RAM eliminates the need for work on site and traveling. TPEM CC Factory Fit is PLE-certified for global deployment.

On request, existing TPEM cabinets can easily be updated with a retrofit kit. The retrofit kits are suitable for all existing TPEM cabinets, and their functionality and look and feel are equivalent to those of the ex-works integration. The retrofit kit contains all required cabling and terminals.

Increase the Availability of Your CHP Plant with MWM RAM. Contact Us Now!

Gas engines & Products

Distributed Power Plants

MWM stands for highly-efficient and eco-friendly combined heat and power (CHP) plants for distributed power generation

Gas Engines / Generator Sets

Gas Engines, gensets, biogas and natural gas generator sets, power generators for decentralized energy supply by MWM, one of the world's leading providers of highly efficient, eco-friendly plants.

Contact Service

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany

T +49 6 21/3 84 – 0 F +49 6 21/3 84 – 88 00 E service@mwm.net