CHP for Industrial or Commercial Facilities

GLOBALFOUNDRIES, Dresden, Germany

- Energy efficiency of up to 90%

- Lower energy costs than with separate heat and power generation systems

- Lower emissions than with separate heat and power generation systems

Reduced Operating Costs due to a Highly Efficient CHP, Distributed Generation or Emergency Standby Power

In many industrial installations such as production facilities, refineries and regional district heating plants, the operating costs are reduced by implementing a combined heat and power system (CHP) with clean pipeline natural gas as a fuel. MWM gas powered gensets can simultaneously deliver electrical energy for electrical loads and heat energy for the heating of industrial plants. While the efficiency of separate grid power and natural gas boilers is often less than 50%, our CHP projects offer:

- Energy efficiency of up to 90%

- Lower energy costs than with separate heat and power generation systems

- Lower emissions than with separate heat and power generation systems

If the recovery and use of waste heat is not profitable, many commercial installations can still yield financial benefits by means of distributed electric power, local electric power for captive use or with an emergency standby power plant. This is especially the case if one of the following conditions is true:

- The local electric grid is unreliable.

- Natural gas is an inexpensive alternative to grid electricity.

- Generators can be applied during daily peak load times to avoid high electrical utility demand charges (also know as peak shaving).

Any gas-fueled MWM gas engines can be specially configured for applications involving heat recovery.

MWM provides customized CHP packages, including any necessary mechanical equipment and controls to capture thermal energy from engines and transfer it to an industrial plant. In addition, MWM offers exhaust treatment for heavily regulated emissions environments and parallel switchgear systems for energy utilities to enable the sale of surplus electrical energy to the local power grid.

The total energy cost savings of such systems can more than offset the total owning and operating costs, delivering a payback in as little as two to three years, depending on local energy pricing and policies.

Here’s how Distributed Generation and Emergency Standby Power Work

Although diesel fueled emergency power systems will always be the solution of choice for life safety emergency standby systems, there has been an increasing move toward natural gas fueled standby power systems in recent years. Typically installed with an automatic transfer switch (ATS) or paralleling switchgear control for multiple generator sets, these systems sense when a utility outage occurs and automatically start the backup power system and transfer power to the local power grid. When normal grid power returns, the control system automatically switches back and shuts down the emergency generator.

Gas engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

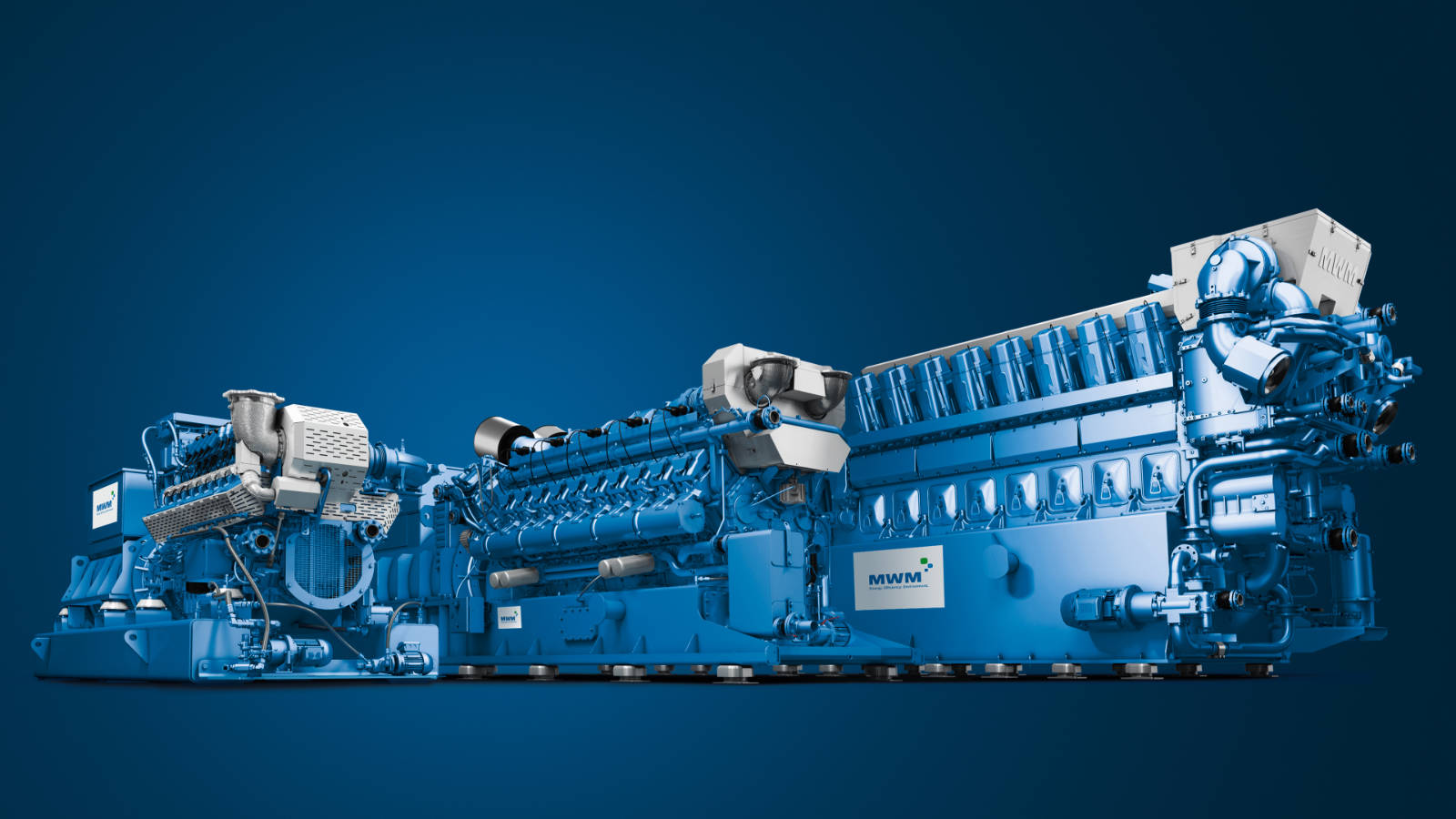

Gas Engines / Generator Sets

Gas Engines, gensets, biogas and natural gas generator sets, power generators for decentralized energy supply by MWM, one of the world's leading providers of highly efficient, eco-friendly plants.

Contact Sales

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany