Operations

Main MWM Factory in Mannheim Offers Ideal Conditions for Premium Manufacturing Quality

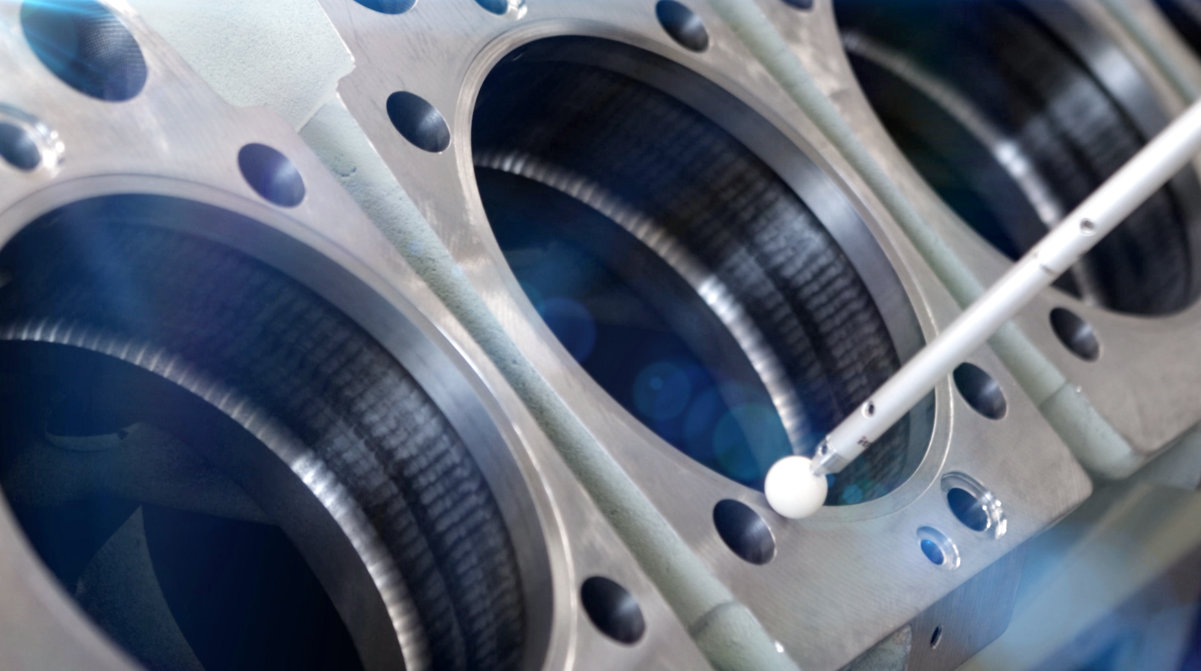

At its Mannheim factory, MWM bundles all production stages under one roof. The company’s experience of more than 150 years and the long tradition in engine building contribute to the high quality of the production lines. This experience is complemented by ongoing further development and improvement of the plants and power generators in cooperation with MWM partners.

Manufacturing and Assembly

The internal production of all central components ensures a high quality level. MWM’s investments in the expansion and modernization of its production sites enable state-of-the-art manufacturing and provide sufficient capacity for expected growth scenarios and the associated demand increases.

PRIVACY NOTE: If you play a video, privacy regulations of YouTube apply.

All language versions of the video on YouTube: EN

Download Video: EN

(1.5 Minuten, HD, 205 MB, MP4)

State-of-the-Art Robot Technology in the Production

The new crankcase deburring robot has been in use for the 2016 and 2020 series since May 2011. This unit enables most of the time-consuming manual deburring to be performed automatically, in a very short process time. Automated deburring greatly contributes to a higher quality standard. Apart from the improved quality and significantly reduced flow times, the precise tool guidance has also enabled much a much longer tool life.

Hovering Through the Material Lane

Using a flexible hovering assembly system, all variants can be produced in different batch sizes with a minimum logistical overhead. The material is made available directly at the point of assembly, while the capacity can be controlled individually by means of the staff deployment.

Using specially designed jig technology, the new center for large conrod processing is capable of a manufacturing precision of up to 1/1000 mm. In combination with a specific sanding procedure, the conrod satisfies highest quality standards and guarantees perfect transmission. Optimized manufacturing times provide an increased capacity for covering the growing demand in coming years.

Quality Assurance

For MWM, quality is the Number One priority. MWM’s years of experience and expertise are already evident in the design and development of components. Another quality feature is the collaboration with first-class suppliers. No matter whether outsourced or manufactured internally, all components are checked according to strict quality criteria.

With its modern, fully automated measurement technology, the 3D measurement device that is integrated in the manufacturing process ensures the production of high-quality components. In compliance with MWM’s high quality standards, even minute process variations are detected and eliminated immediately.

Test Facility

The MWM genset test facility was expanded and modernized in 2008. Thanks to the highly innovative genset testing technology, MWM is capable of simulating and duly testing all common customer requirements. Flexible transformers and an inverter system form the core of the test facility and enable the simulation of all customer requirements.

The electricity produced at the test facility is used to supply the plant, resulting in reduced CO2 emissions and energy costs. The excess power is fed into the grid of the local energy supplier.

Every year, MWM produces much more electricity than the entire factory consumes.

By combining standard test facility automation and expanded energy management, MWM ensures maximum quality and efficiency.

Staff and Processes

MWM invests, not only in state-of-the-art production, but especially in its staff and processes, thereby ensuring ongoing improvement of the manufacturing processes and thus of the products. A central lean manufacturing team supports the teams on site with lean manufacturing process tools in order to continually optimize the productivity and flow time.

All operational employees regularly participate in continuous process improvement (CPI) training sessions and play a key role in the development of the site by implementing improvements in special workshops.

From the first customer inquiry to the commissioning of gensets, MWM operates on the basis of clearly defined, transparent processes. The quality and efficient delivery times achieved by means of this approach are unique features of MWM.

Logistics

At the MWM logistics center in Lorsch, Germany, MWM coordinates the global shipping of service parts via sea, land, and air freight.

Find out more

Gas engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Contact Sales

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany

Please fill out our contact form and we will call you back!