Online CHP plant maintenance with VPN router

One building block in MWM’s modern, comprehensive service concept is remote access to the plant control systems of cogen power plants via internet. This type of remote maintenance and diagnostics is not entirely new, yet it has undergone a significant technical evolution over the past few years. This is an example of a remote access system which can still be found at many cogeneration plants: The customer uses a software application to log on to the plant control systems per IP modem via the internet. This technology has become quite outdated, however, and provides potential security risks. The modem requires a static IP, which means added monthly costs and overhead compared to a standard internet line. Remote access is established via an incoming connection into the customer’s network, the connection is relatively slow due to the high data complexity, and it requires expensive components. Therefore, MWM relies on a more modern version of remote maintenance by means of a VPN router instead of a modem.

Online CHP plant control systems

CHP plant control systems via secure access

The analog modem or (static) IP modem for remote maintenance via the internet will be replaced by an on-site VPN router (Remote Plant Gateway – RPG). The advantage over remote access to plant control systems via modem: The VPN router for the customer’s CHP plant autonomously establishes an outside connection, i.e. only outgoing connections via standard ports are utilized. There are no incoming connections into the customer/plant network for remote maintenance. Equipped with an additional wireless antenna and a SIM card, the VPN router is even capable of creating a mobile data link.

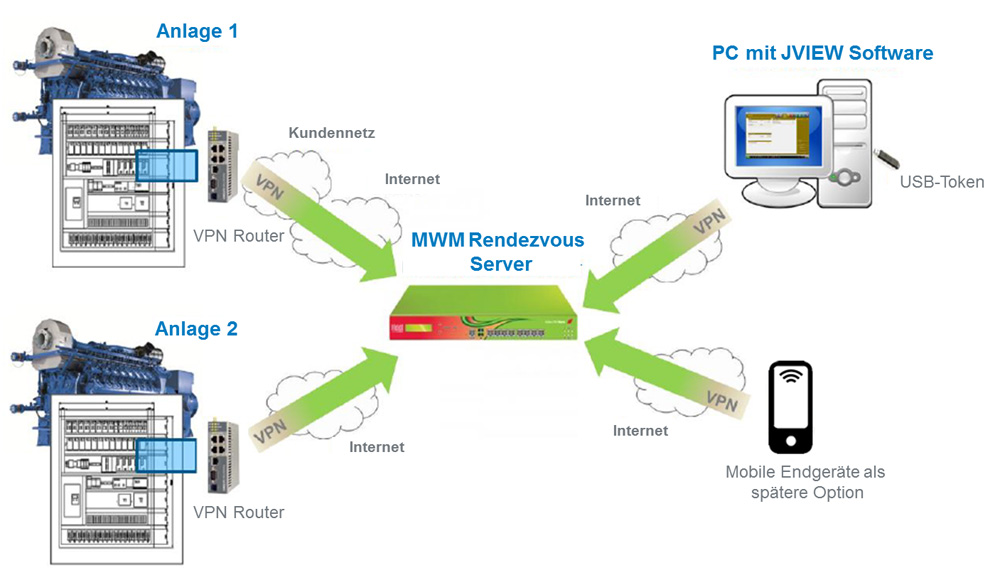

Here is how it works: The VPN router installed in the customer’s plant autonomously connects to the MWM Rendezvous Server (RVS). The RVS is located in the MWM data center in Mannheim and is the “meeting point” in the internet. The customer can link up to the RVS from a PC, laptop, etc. Once logged on to the RVS, the customer is provided an overview of his systems that are available for connection over the internet. He can establish a secure connection to the system(s) and remotely operate the TEM (Total Electronic Management) as engine/genset control systems. In order to view the plant control systems on the customer’s computer/laptop, the J-View software application is required.

Advantages of plant control systems via internet

This type of remote maintenance offers MWM customers several advantages. For example, the VPN remote maintenance can be simply integrated into existing company networks – even for existing systems, maintenance access per Remote Plant Gateway (RPG) can be easily retrofitted. Wherever an internet connection is available, secure access to the system is possible via VPN – even worldwide. What’s more, the system consisting of the VPN router and RVS always operates according to the latest security guidelines. The access offers dual safeguards through a password log-in and a USB e-token, a type of electronic key. The customer can link up to the MWM RVS from a PC or a laptop computer, and work is underway to allow access via mobile end-user devices. Via the RVS, the customer establishes a VPN connection to the system and can remotely operate the control software with the help of the J-View application.

Security

In order to ensure the highest level of security for remote access to CHP plants, the connection to MWM’s Rendezvous Server requires two levels of authentication with a user name and password, along with a USB e-token from MWM. The token, a form of electronic key, contains a user certificate, which is valid for a particular period of time.

Roll-Out

The start of the new remote access to plant control systems is planned for the near future and will then be available to clients. Please contact your sales manager. You may also contact our sales team under: sales@mwm.net.

For technical details please contact our product management under: productmanagement@mwm.net.