Agricultural Biogas

Géotexia Biogas Plant, France

- Reduction of carbon emissions through the decomposition of naturally occurring methane

- Reclamation of valuable land space normally utilized for purifying organic wastewater

- Elimination of odor and infestation problems that accompany the decomposition of organic material

Biogas: A Highly Efficient and Profitable Alternative for Power Generation

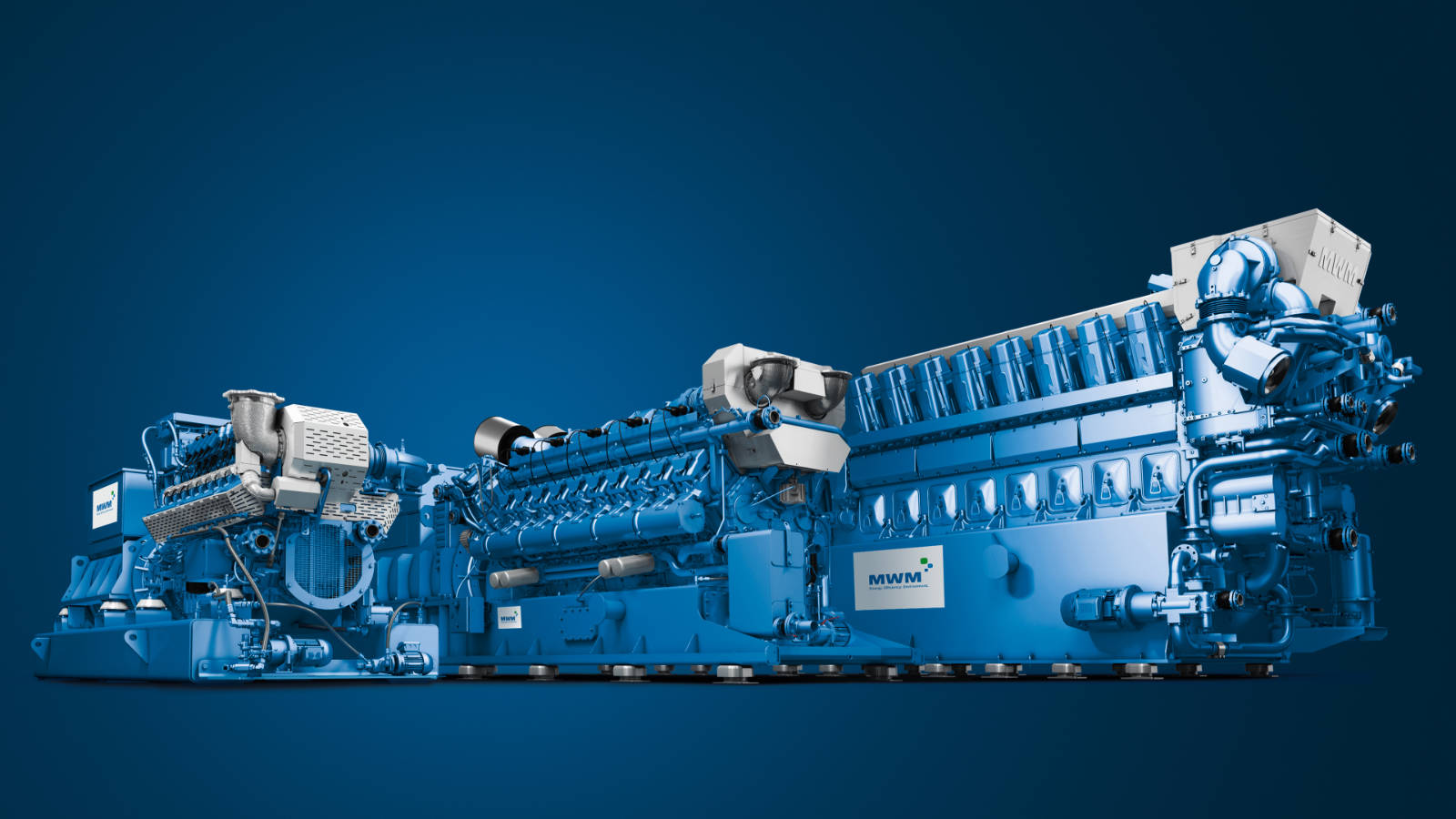

MWM offers durable and reliable solutions for the use of biogas. This gas, a by-product of many agricultural, food processing and industrial processes, is used today as a fuel for power generators with gas engines (gensets or generators).

Advantages of Using Own Biogas in Agricultural Power Plants (Cogeneration Systems)

- Reduction of carbon emissions through the decomposition of naturally occurring methane

- Reclamation of valuable land space normally utilized for purifying organic wastewater

- Elimination of odor and infestation problems that accompany the decomposition of organic material

The procurement costs can lead to considerable long-term savings and enable companies to pursue ecological responsibility goals.

Biogas from Renewable Energy Sources and Biogas Plants

Energy from biomass can make a tremendous contribution towards sustainable power supply. Currently biogas offers the highest user benefits and the best use of the energy potential of biomass.

Biogas is produced from the anaerobic fermentation of organic material in the fermenter of a biogas system. Biogas, consisting primarily of methane and carbon dioxide, is created during the anaerobic decomposition of organic waste materials. This gas has a methane CH4 content from 45 to 70 percent. During its combustion, it only releases as much CO2 as the plants absorbed during their growth. Cogeneration power plants that produce electricity from biogas prevent emissions that would otherwise be released by fossil fuels.

Instead of allowing uncontrolled decomposition of these wastes and the release of gases into the atmosphere, they are contained in an oxygen-deprived environment such as a covered lagoon or aboveground steel tank. From there, methane is extracted and burned to generate electricity or heat.

Because of the impurities and inconsistencies in biogas, pretreatment is generally required. However, using a gas engine specifically designed to operate on biogas can reduce the amount of investment in pretreatment.

Our gas engines (generator sets) are engineered to handle fuel with variations in methane content typical of biogas operations.

MWM gas engines are specially designed for the combustion of biogas:

- A crankcase ventilation pump to eject potentially acidic blow-by gases

- Specially designed aftercooler cores, cylinder heads, main bearings and connecting rod bearings that are hardened against corrosive elements

- Differentiated cooling systems to operate at elevated jacket water temperatures to prevent condensation of contaminants

MWM offers gas engines specially matched to biogas, complete systems as well as containers for combined heat and power. These systems achieve the highest levels of efficiency in the various power segments. What’s more, MWM also provides the required system components for gas treatment and purification. For installation of the generator in remote areas, the generated energy can also be used exclusively by the system.

Gas engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Container Cogeneration Plant

Compact modules for the TCG 3016, TCG 3020 and 2020 gas engines. Complete turnkey systems for special applications.

Gas Engines / Generator Sets

Gas Engines, gensets, biogas and natural gas generator sets, power generators for decentralized energy supply by MWM, one of the world's leading providers of highly efficient, eco-friendly plants.

Contact Sales

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany