Energy Solutions for Greenhouses

Delta Energy B. V., The Netherlands

- Energy efficiency of more than 90%

- Lower energy costs than with separate heat and power generation systems

- Lower emissions than with separate heat and power generation systems

- Opportunities to boost revenues through the export of electrical power

- Carbon dioxide plant fertilizer

Highly-efficient CHP Plants: Energy Efficiency in Plant Nurseries

The key factor when running greenhouse operations is not only being able to generate off-grid electric power and heat for captive use but also having the option of using the combustion by-products from the natural gas consumed. Thus the exhaust gases are also used to promote plant growth.

Heating the greenhouses requires the largest energy consumption in plant nurseries. Second to this is possible preheating of irrigation water and the heating of retail shop areas. Electrical power is mainly used for lighting and compressed air, along with the operation of boilers, as well as for process control purposes. In the greenhouse facilities, the operating costs can be reduced through implementation of a combined heat and power system (CHP) with clean pipeline natural gas as a fuel.

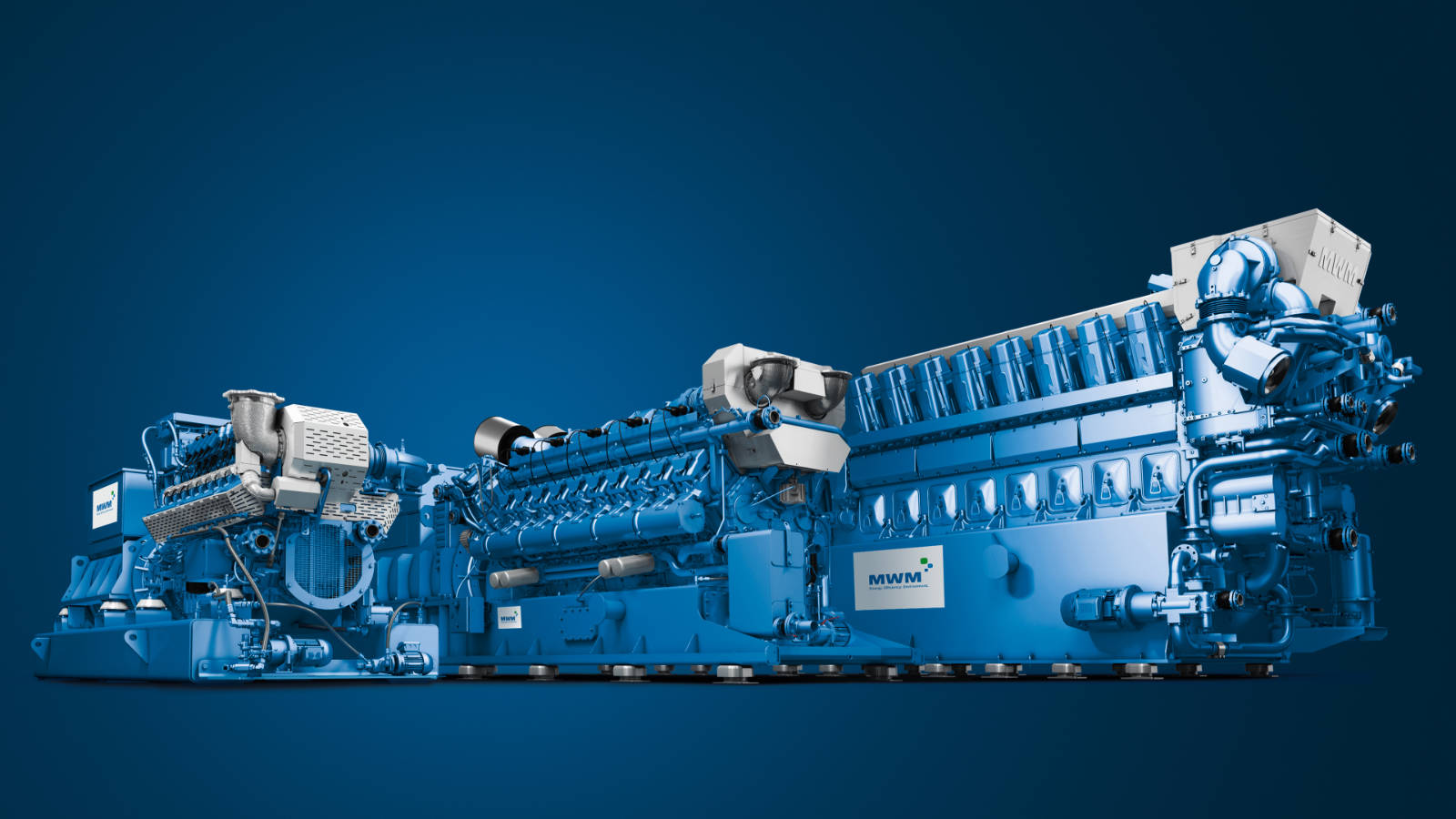

Our MWM gas engines (gensets) can deliver electrical power for electrical loads, heat energy for the heating of greenhouses, and reusable carbon dioxide from the engine exhaust as organic fertilizer.

The Advantages of Cogeneration Systems in Greenhouses:

- Energy efficiency of more than 90%

- Lower energy costs than with separate heat and power generation systems

- Lower emissions than with separate heat and power generation systems

- Opportunities to boost revenues through the export of electrical power

- Carbon dioxide plant fertilizer

The Ideal Fuel for Our Combined Heat and Power Systems: Natural Gases and Gases Similar to Natural Gas

Any natural gas-fueled MWM gas engines can be specially configured for applications involving heat recovery. The gas engine runs a generator for the production of electrical power, while jacket water and/or exhaust cooling circuits are fed through heat exchangers to transfer the waste heat from the engine to a hot water or steam circuit. The hot water is collected and used for heating the greenhouses. The carbon monoxide can be removed with oxidation catalysts, and the urea-based SCR system can be used to reduce nitrogen oxide emissions down to just a few ppm. Afterwards, the exhaust gases are so clean that they can be fed to the plant roots as fertilizer and boost the farmer’s profit.

As the heat energy is decisive for the dimensioning, the electrical power generated in greenhouse facilities frequently exceeds local demand.

In many European countries, high-efficiency power generation is subsidized via production certificates. The lion’s share of the electrical power generated is exported into the local grid. In other parts of the world, greenhouse horticulture relies on similar solutions due to grid unreliability and unfavorable economic constraints.

Customized CHP Solutions from MWM

MWM provides customized CHP package solutions, including any necessary mechanical equipment and controls to capture thermal energy from engines and transfer it to a greenhouse facility. In addition, MWM offers the necessary exhaust treatment, along with parallel switchgear systems and controls for energy utilities to enable the sale of surplus electrical energy to the local power grid.

The total energy cost savings of such systems can more than offset the total owning and operating costs, delivering a payback in as little as two to three years, depending on local energy pricing and policies.

Gas engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Gas Engines / Generator Sets

Gas Engines, gensets, biogas and natural gas generator sets, power generators for decentralized energy supply by MWM, one of the world's leading providers of highly efficient, eco-friendly plants.

Contact Sales

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany