Early involvement in production processes

The new training concept at MWM is taking an unusual path – departing from traditional classroom instruction and moving towards self-directed learning and cooperative support of the trainees among themselves. Today, rather than having to learn content by rote according to training directives, young people at MWM are encouraged to show initiative and a willingness to achieve – important prerequisites for the new concept that places an emphasis on dynamic acquisition of knowledge by the learners themselves.

“Only those who take on responsibility early during training and learn to create quality can also develop a quality awareness for their work”, of this Manuel Sauter, Head of Industrial Apprenticeship at MWM, is certain.

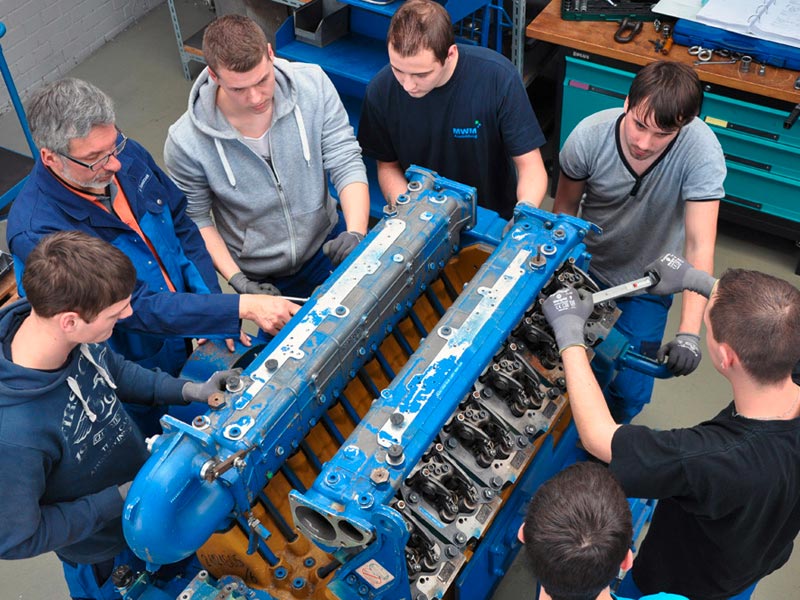

Learning in Practice for Real-Life Conditions

That is why there is a clear practical focus in the teaching of knowledge. Already in the first year, commercial and technical trainees (industrial mechanics and mechatronics technicians) are involved in real work processes in the field of production and assembly of gas engines. The head of training knows that by working on real projects, the motivation of the trainees is vastly different than if they were preparing so-called “sample workpieces”.

In this, the learners set their own learning pace, and group work and mutual support are especially important. Developing a sense of ownership at an early stage is intended to not only qualify them from a technical standpoint but also prepare them for constantly changing (work) situations in which they will be required to flexibly solve tasks and problems.

Individually Promoting and Challenging Talent

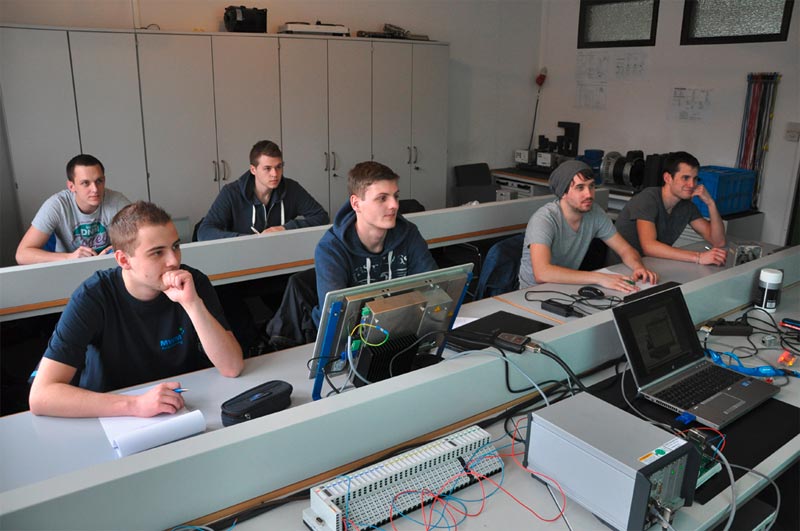

In the training center in the Mannheim headquarters, there are up to four learning modules that the trainees can complete. Units 1 and 2 are obligatory for all commercial and technical trainees, and Units 3 and 4 are geared to the requirements within the technical departments.

In the approx. 1-week learning modules in groups between 10 and 12 participants, first the theoretical fundamentals of each module are learned, then they are applied in practice. In the training center, the trainees also work under real conditions, as from the outset it was designed for the training of employees, customers and their employees or dealers. Here regular seminars are offered for further qualification. During the seminar planning, the training modules of the trainees are also taken into consideration.

Preparing Trainees – Step by Step

The first module (Step I) involves core qualifications in technical physics and natural science fundamentals of engineering. Building on these basics, the second module (Step II) provides specialized instruction in product-related engine technology for gas engines. Module 3 (Step III) teaches the required procedures for service and preventive maintenance of machines and systems, which puts the practical work with MWM products into focus. In this process, trainees are guided by qualified trainers.

“Regardless of which training you have chosen, during the trainee program you will learn and apply technical knowledge, gain trust in your own abilities and in others’ and quickly become integrated in a team”, the responsible trainers Günter Tomiczek and Werner Schlenker both agree. The last module (Step IV) deals with interdisciplinary and product-related systems technology. Here the participants become immersed in control, regulation and monitoring of genset operations.

Jürgen Bauer, head of the Mannheim Training Center, explains the training concept as follows: “First the theoretical fundamentals are taught, then we will apply them in practice. After developing a skill set in core and specialized qualifications, we send the trainees to the individual technical departments, where concepts are solidified in practice.”

The requirements for the trainees and thus also for the training itself are constantly increasing in the course of globalization. With the new training concept, which places an emphasis on market needs, practical work and requiring young people to take early responsibility, MWM is rising to the challenge of preparing qualified employees for the future. With the beginning of the new training year in September 2013, MWM GmbH is employing 47 commercial and technical trainees in all four apprentice years.