MWM Premium Antifreeze -20 & Antifreeze Advanced for MWM Gas Engines

High Performance Coolant

- Suitable for all MWM diesel and gas engines

- Suitable for all plant configurations (exhaust heat exchanger in the engine and heating circuit)

- MWM Premium Antifreeze -20 contains silicate – effective corrosion protection due to hybrid technology

- MWM Antifreeze Advanced – silicate free – reliable corrosion protection with exclusively organic inhibitors

High-Performance Coolant for MWM Diesel and Gas Engines

- Suitable for all MWM diesel and gas engines

- Suitable for all plant configurations (exhaust heat exchanger in the engine and heating circuit)

- MWM Premium Antifreeze -20 contains silicate – effective corrosion protection due to hybrid technology

- MWM Antifreeze Advanced – silicate free – reliable corrosion protection with exclusively organic inhibitors

- Amine, nitrite and phosphate-free

- Small deposits on thermally high-loaded components such as the cylinder liner

- Extended exhaust heat exchanger service lives due to low total hardness

- Simple handling as a ready-mix

- Optimized glycol content for safe frost and corrosion protection with a maximum heat transmission capacity

Permanently Safe Operation of Gas Engines

With increasing engine power and higher levels of efficiency, the thermal loading of engine components adjoining the combustion chamber increases. The main task of the coolant is to discharge the combustion heat from these components (component cooling) and provide it to the customer as useful heat. The coolant is therefore not only responsible for a continuously safe engine operation, but also for efficient use of the plant.

MWM – Many Years of Experience with Gas Engines

Like lube oils, coolants are tested in intensive field tests and approved for use. Based on the long-standing experience of our development engineers, as well as extensive assessment of field experiences of the MWM service organization, the inhibitor technologies for MWM Premium Antifreeze –20 and MWM Antifreeze Advanced have been selected together with a strategic partner.

High Profitability

The focus when selecting the MWM Premium Antifreeze –20 inhibitor technology was on a low formation of deposits on thermally high-loaded components, since the heat transfer is inhibited by the formation of isolating layers in these areas (primarily cylinder liner and cylinder head), which may have adverse effects on oil consumption and valve wear. MWM Premium Antifreeze –20 is characterized by excellent heat transfer, safe frost and corrosion protection and simple handling. The availability and economic efficiency of the plant is increased due to the use of MWM Premium Antifreeze –20.

The inhibitor technology for MWM Antifreeze Advanced was selected to minimize the deposit on components subject to high thermal stress and to maximize the lifetime of the coolant. The high-performance coolant is free of silicate, phosphate, amine, nitrite, and boron and is suitable for all MWM gas engine series. In this MWM coolant, only organic inhibitors are used for corrosion protection. These do not leave any hard deposits on the engine components, which could impair the heat transfer. The corrosion protection inhibitors are not consumed during operation and thus enable a long useful life of the coolant. As MWM Antifreeze Advanced is a ready-to-use mixture, the coolant always has the right inhibitor and glycol concentration. This prevents incorrect dosing.

Optimum Coolant Composition: Protection Against Corrosion and Consumption

The heat conductivity of coolants drops with an increasing glycol content. With a glycol content of 35 Vol. %, MWM Premium Antifreeze –20 and MWM Antifreeze Advanced are the optimum products for safe frost protection up to –23 °C and have very good heat transmission properties at the same time.

Non-organic and organic inhibitors are used in MWM Premium Antifreeze –20 as means of corrosion protection. These form a thin, heat-permeable protective layer on the wetted components.

With MWM Antifreeze Advanced, only organic inhibitors are used as corrosion protection. These do not form any hard deposits on wetted components, which could impair the heat transport.

In order to ensure reliable protection of the engine, the correct inhibitor concentration of the coolant is particularly important. Overconcentration poses the risk of damage to wetted components, and too low concentration of the inhibitor cannot guarantee a sufficient corrosion and cavitation protection. If cooler frost protection concentrates are used for preparing the coolant on site, the correct composition of the mixing water must also be considered, otherwise there may be deposits in the area of the exhaust heat exchanger.

As a read-mix, MWM Premium Antifreeze –20 and MWM Antifreeze Advanced always have the correct inhibitor and glycol concentration – an incorrect dosage is thus prevented. MWM Premium Antifreeze –20 and MWM Antifreeze Advenced are suitable for all plant configurations and can be comfortably filled during maintenance.

Typical Material Properties of the MWM High Performance Coolants Premium Antifreeze -20 and Antifreeze Advanced

| Material properties | MWM Premium Antifreeze -20 | MWM Antifreeze Advanced |

|---|---|---|

| Product basis | Monoethylene glycol | Monoethylene glycol |

| Product group | contains silicate | free of silicate |

| Color | turquise | red-orange |

| pH value | 8.1 | 8.4 |

| Kin. viscosity at 40°C | 1,81 mm2/s | no information |

| Density | 1063 kg/m3 | 1056 kg/m3 |

| Total hardness | < 1°dH | < 1°dH |

| Glycol content | 35 vol% | 35 vol% |

| Anti-freeze protection up to | -23°C | -23°C |

Availability of the MWM High Performance Coolants Premium Antifreeze -20 and Antifreeze Advanced

| Available in | |||

|---|---|---|---|

| Canister | 20l | ||

| Barrel | 205l |  | |

| IBC | 1000l |  | |

MWM Premium Antifreeze -20 – Product Data Sheet

MWM Antifreeze Advanced – Silicate Free – Product Data Sheet

MWM Premium Protect – Product Data Sheet

High-performance corrosion protection ready-mix for MWM gas engines: With increasing engine power and higher levels of efficiency, the thermal loading of engine components adjoining the combustion chamber increases. The main task of the coolant is to discharge the combustion heat from these components (component cooling) and provide it to the customer as useful heat.

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

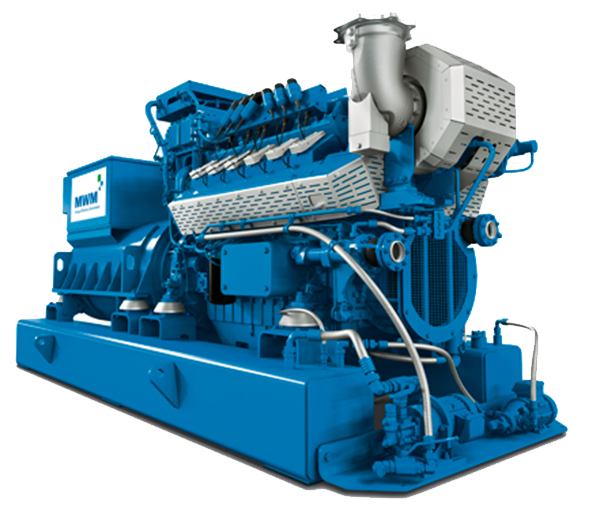

Gas engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Container Cogeneration Plant

Compact modules for the TCG 3016, TCG 3020 and 2020 gas engines. Complete turnkey systems for special applications.

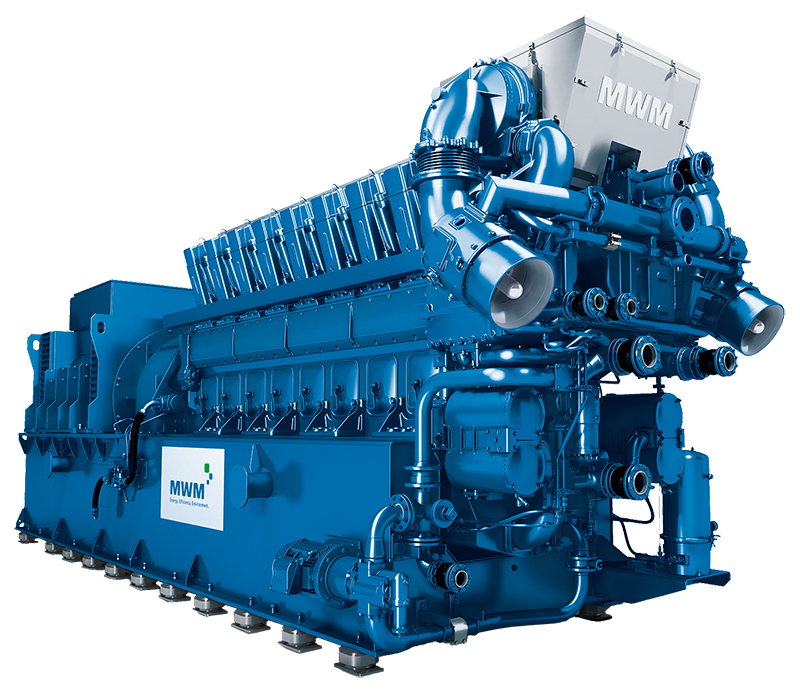

Gas Engine TCG 3016

New development – greatly reduced operating and installation costs and fully digitized power plant control.

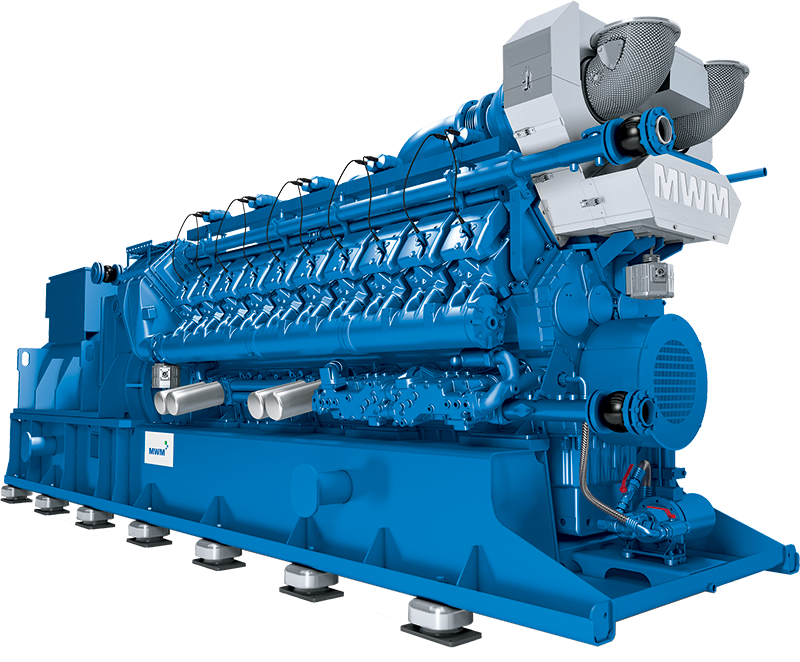

Gas Engine TCG 2032

High reliability. Low operating costs. Gas types: natural gas, landfill gas, sewage gas, mine gas, coke oven gas. Mainly used in large IPP projects with up to 100 MWel.

Gas Engine TCG 2020

Best electrical and thermal efficiency in its class. All gas types: natural gas, biogas, mine gas, landfill gas, sewage gas.

Contact Service

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany

T +49 6 21/3 84 – 0 F +49 6 21/3 84 – 88 00 E service@mwm.net