Flexibility with MWM: Future-Proof Strategies for Needs-Oriented Energy Feed-in by Biogas Plants (Flex Bonus)

Mannheim, May 11, 2016

Since the amendment of the German Renewable Energies Act (EEG), biogas plant operators have been able to market power from biogas plants directly and switch from the fixed feed-in tariff system to direct marketing. In collaboration with a listed power marketer, plant operators can thus generate more income. Additionally installed combined heat and power (CHP) plant capacity enables operators to abandon permanent operation in favor of flexible operation according to schedule. To enable a power-controlled operating mode, gas and heat quantities need to be buffered. Thus, power can be systematically generated profitably during high-price periods on the market. According to the EEG 2012, investments in such power plants are subsidized with the flex bonus.

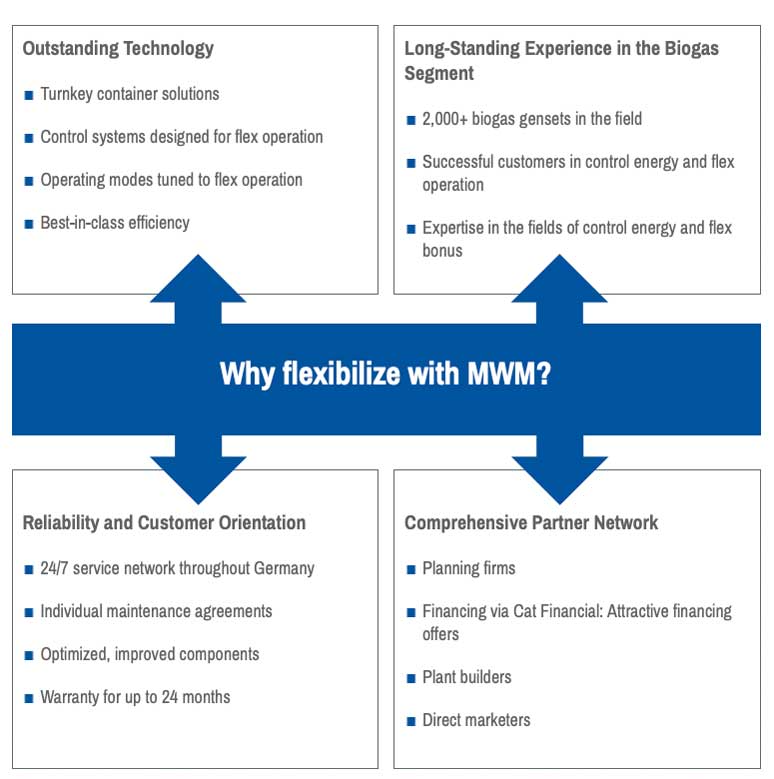

As a competent partner, MWM assists plant operators with its extensive experience in the development and production of gas engines and power gensets for decentralized energy supply. To improve the efficiency of such plants, the biogas variants of the TCG 2016 and TCG 2020 V12, V16, and V20 have been optimized for higher electrical efficiency. Apart from being more eco-friendly and durable, the enhanced biogas variants of the gas gensets also feature other key benefits. For example, gensets in the output range from 400 to 2,000 kWel fulfill the elevated requirements of a broad application spectrum and ensure efficiency, reliability, flexibility, environmental compatibility, low TCO, and high profitability.

Flexible Operation of Gas Engines

Due to the needs of the energy reform of the new energy market system and the increasing level of decentralization, the subject of network stability and, as a result, the higher level of flexibilization of power producers and consumers are growing in importance. Currently, these requirements apply primarily to the German energy market. Nevertheless, many European countries have similar balancing energy markets with diverse regulations and requirements.

In this context, gas gensets represent an optimum supplement in the energy mix, as their flexible operation can balance volatile energy sources like wind and photovoltaics. In view of the growing need for flexible genset operation, the MWM gas engines of the TCG 2016 and TCG 2020 series, which are suitable for flexible operation, have been examined for the current requirements of transmission system operators and approved for operation with special maintenance schedules.

Due to the different operating conditions, the replacement intervals must be differentiated. Apart from the operating hours, the start-up frequency and time period are also relevant. The changed criteria thus affect the maintenance schedules and the service cost calculation. The operating modes “permanent operation” and “flexible operation” are defined as follows:

| Permanent Gas Engine Operation | Flexible Gas Engine Operation |

|---|---|

| More than 3,000 operating hours a year and | Less than 3,000 operating hours a year or |

| Fewer than 1,200 engine starts a year and | More than 1,200 engine starts a year or |

| More than two operating hours per engine start | Less than two operating hours per gas engine start |

Ahe Biogas Plant: Exemplary Biogas Plant with Flexible Operation

The plant of Ahe Biogas GmbH, which is situated in the special “Bioenergy” zone, went live in 2012. From the outset, it was designed and built so as to provide control energy. To market the power, a cooperation agreement has been entered into with Next Kraftwerke. The company actuates the three installed MWM gas gensets of the TCG 2016 and TCG 2020 engine series of the biogas plant up to 20 times a day via a remote control unit (Next Box). In this way, the plant operation can be aligned with the power prices of the intraday market of the EPEX spot exchange in a needs-oriented manner, and valuable control energy can be supplied to the transmission system operators.

Ahe Biogas Plant

Ahe Biogas Plant

The Cologne-based company Next Kraftwerke can dispose freely over the CHP plants and switch the plant off and back on at quarter-hourly intervals. It takes five minutes for the system to be set from full load to zero or from zero to full load. The marketing of the available flexibility on the control energy market and via the EPEX spot market has been under way for more than a year. “We have made very good experiences with the responsiveness of the MWM engines”, confirms the power marketer Next.

The average power generation capacity of the biogas plant (nominal capacity) is approximately 1.4 MW, while the installed CHP plant capacity is almost 4 MW. Additionally, the facility has a gas storage volume of 14,000 m³ above the plant’s four digesters and digestate storage units. The biogas facility in Beverstedt in North Germany thus boasts an enormous flexibility balancing part of the fluctuating solar and wind power generation.

Time to Boost Plant Flexibility and Income

After many successful and bountiful years, the biogas industry is now faced with major challenges. In view of the constantly sinking power feed-in subsidies, the construction of new biogas plants has become virtually impossible under economic considerations. However, as far as existing plants such as the one in Ahe are concerned, there are attractive possibilities for boosting the income and guaranteeing the future.

By means of the flexibility bonus, the German government subsidizes the flexible operation of biogas plants. The subsidy of €130 per additionally installed kW of electrical capacity is paid for 10 years or until the plant’s EEG subsidy runs out, and offers significant opportunities.

Applying for the bonus but delaying the start of flexibilization means losing valuable subsidization time. The amended EEG also enables existing biogas plants to benefit from the flex bonus. The flex bonus rewards the provision of installed CHP plant capacity in excess of the capacity used over the year, on average.

| Facts: | Advantages for plant operators: |

|---|---|

| High, steady subsidy | CHP plant & parts of the peripherals are financed |

| Needs-oriented feed-in | Additional income via power exchange (1.5 – 2 c/kWh) |

| CHP plant availability | 100% biogas utilization => substrate savings and thus higher income |

| Efficiency increase (new CHP plant) | No pressure to provide 100% availability => “calm nights” |

| Fewer operating hours | Hidden reserves (gas engine runs only 20,000-40,000 hours in 10 years) |

| Flex CHP plants have a longer useful life | Better utilization of high prices on the power market |

| Perspective after EEG subsidy |

Further information on the reference project Ahe and on the subject of biogas plants with flexible operation is available under: Use the Flexibility Bonus – Flexible Biogas Future with MWM (in German)

Flexible Biogas Future with MWM

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 6 21/3 84 – 87 48

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 6 21/3 84 – 86 33

E mwm-press@cat.com