1985

MWM G 234 V8 – the first volume-produced gas engine with three-way catalytic converter

High output, low emissions

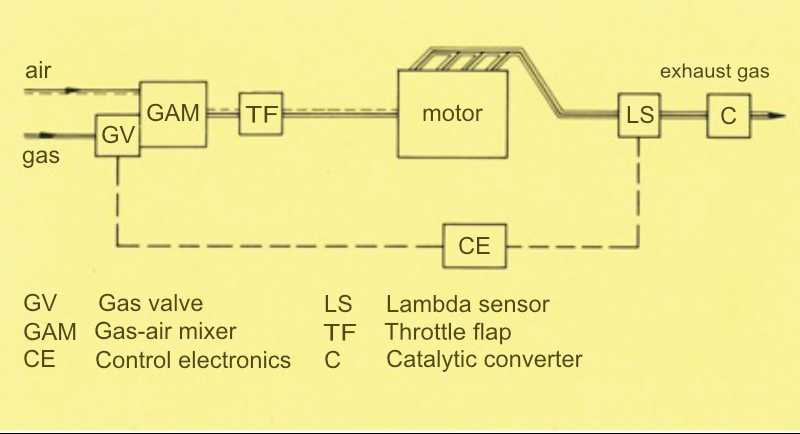

The gas engines of the G234 series (6 cylinders with 90 kW, 8 cylinders with 120 kW and 12 cylinders with 180 kW) featured an output that was 30 percent higher than that of the predecessor series. To reduce exhaust pollutants, the engine’s exhaust tract was equipped with a three-way catalytic converter that had to be operated at an air ratio of lambda=1 in order to achieve its optimum cleaning performance. With this air ratio, a naturally aspirated gas engine was able to achieve the highest possible performance. Across the engine’s entire output range, an electronically controlled mixing system (lambda 1 control) kept the air ratio stable within the narrow lambda window of 0.986 to 0.990. This precise mixture was achieved with a lambda sensor in the exhaust gas, an electronic control unit, and an actuator on the gas mixer. This enabled the three-way catalytic converter to significantly reduce emissions – NOx to less than 150 mg/Nm3, CO to less than 150 mg/Nm3, and HC to less than 90 mg/Nm3.

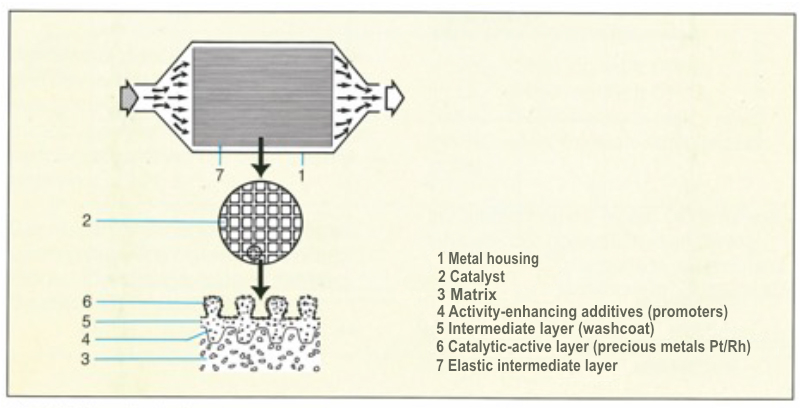

The three-way catalytic converter consisted of a ceramic or steel foil matrix with many narrow flow channels coated with a platinum-rodium alloy. This is where the reactions to minimize pollutants in the exhaust gases took place. The catalytic converter deployed with the natural gas engine in Weinheim was in permanent operation for over 28,000 operating hours without any significant effectiveness drop. If the catalytic converter had been used in a vehicle, this operating time would have corresponded to 1.4 million km.

The lambda sensor and the three-way catalytic converter were integrated in the engine heat dissipation module, the MWM heating cabinet. The heating cabinet also hosted the cooling water and exhaust gas heat exchanger, the cooling water pump, and the expansion tank.

An MWM cogeneration power plant with G234 V12 gas engines was also put into operation in 1985 at the district hospital in Uelzen. During the commissioning, the customer had the efficiency of the cogeneration power plant measured. The result showed that the system was capable of utilizing 91.2 percent of the primary energy (natural gas) used.

These excellent emission and energy utilization levels were the product of several years of development and optimization of the engine and plant peripherals.

With these systems, MWM was able to offer compact, fully pre-assembled units consisting of a gas engine generator set, an MWM heating cabinet, and a switchboard for cogeneration power plants.

The technology of clean exhaust gases through lambda=1 combustion and a three-way catalytic converter was subsequently also used in the G 604B series. With these two series, generator sets were thus made available in an output range of up to 450 kWel.

With these powerful engine series, MWM secured its leading position in the German cogeneration power plant market for many years.

READ MORE ...

MWM History. Future Needs Tradition.

More about the history of the company, the MWM brand and the experience in developing and optimizing stationary gas engines.

Read moreFoundation of the Motoren-Werke Mannheim A.-G.

April 1922: Sale of Benz & Cie. department “Stationary Engine Construction” officially sealed, new company name: “Motoren-Werke Mannheim A.-G. vorm. Benz, stationary engine construction department”.

Read moreLEARN MORE ...

Image credits and bibliographic reference

Image 1: Cogeneration power plant at the Weinheim indoor swimming pool

Image 2: Schematic diagram of the lambda control system

Image 3: Structure of a three-way catalytic converter

Zacharias F.: Erster Serienmotor mit Katalysator arbeitet im BHKW Weinheim; Sonnenenergie und Wärmepumpen 2 (1985)

Baas H.: BHKW für Kreiskrankenhaus Uelzen mit 91,2% Nutzungsgrad; Sonnenenergie und Wärmepumpe 2 (1986)

«

«