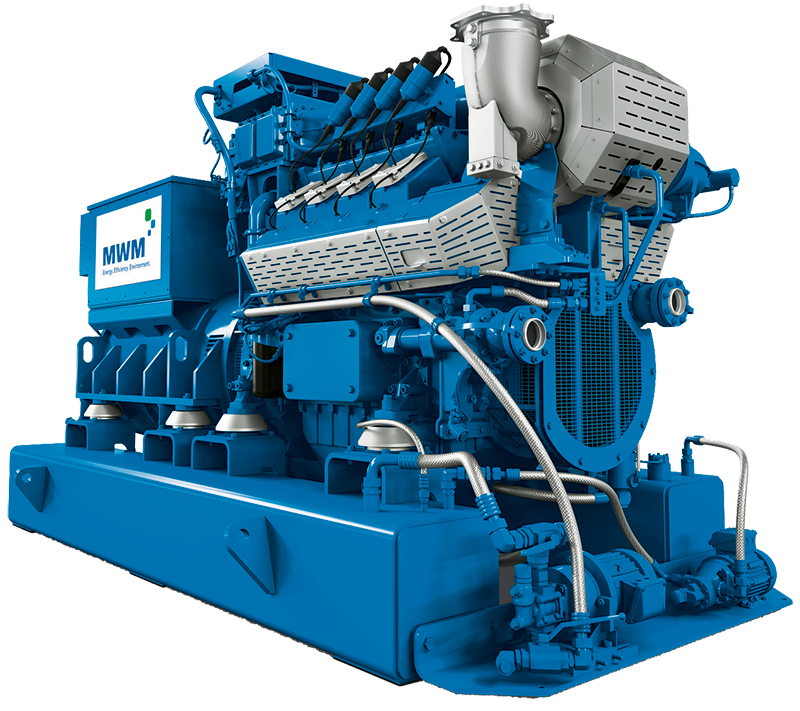

TCG 3016

Gas Engine TCG 3016

400 - 1,000 kWel

New development – greatly reduced operating and installation costs and fully digitized power plant control.

- Output range from 400 kWel bis 1,000 kWel

- Low gas consumption, flexible use of fuel, suitable for all gas types including hydrogen admixtures of up to 25 vol%

- Greatly reduced installation and operating costs

MWM TCG 3016 Gas Engine – Efficiency Goes Digital

The New One. Robust. Efficient. Digital.

- Output range from 400 kWel to 1,000 kWel

- Optimum efficiency: electrical efficiency up to 43 percent

- Low gas consumption, flexible use of fuel, suitable for all gas types: natural gas, biogas, landfill gas, sewage gas, mine gas, hydrogen admixtures and other gases

- MWM retrofit kits available in two editions for conversion for operation with hydrogen admixture of up to 20 vol% and up to 25 vol%

- Greatly reduced installation and operating costs

- Higher reliability and availability through improved robustness

- Low maintenance costs due to longer maintenance intervals

- Very low lubricant consumption and operator-friendly oil management

- The TCG 3016 V16 (S = High density) is specifically optimized for the 1 MWel capacity range, with high stress tolerance for optimum availability, and long useful life

On this page

Video: MWM Gas Engine TCG 3016.

Description – MWM Gas Engine TCG 3016

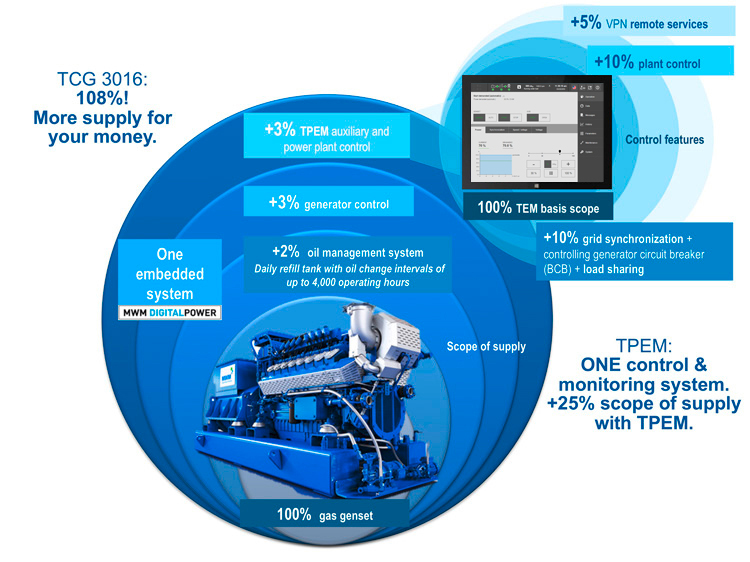

Industry 4.0 – TPEM

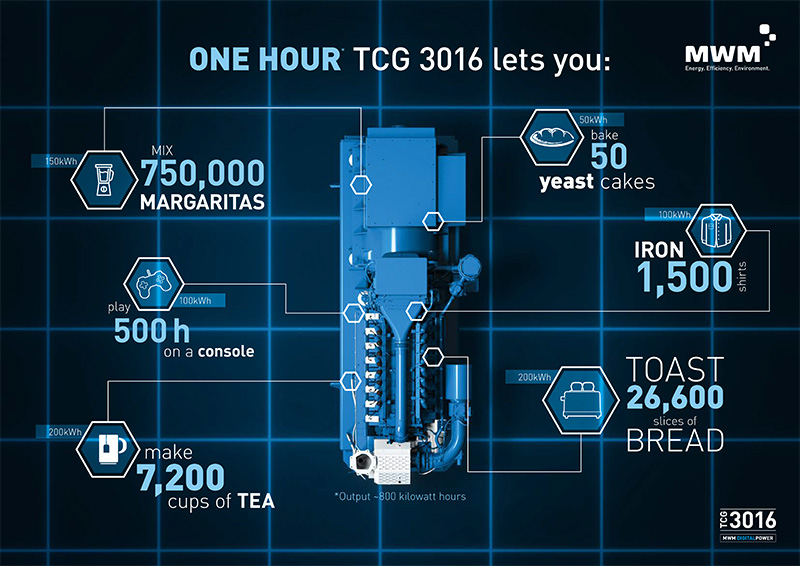

What a TCG 3016 Can Do in an Hour

Performance Data – MWM Gas Engine TCG 3016

Specifications and Service Intervals – MWM Gas Engine TCG 3016

Brochure – MWM Gas Engine TCG 3016

Video: TCG 3016.

DATENSCHUTZHINWEIS: Beim Abspielen von Videos gelten die Datenschutzbestimmungen von YouTube. /// PRIVACY NOTE: If you play a video, privacy regulations of YouTube apply.

The MWM TCG 3016 gas engines are more than merely the next iteration of the proven MWM gas gensets: The new gas engines represent an entirely new development – perfectly tailored to the challenges of Industry 4.0 and the changed framework conditions of a dynamic market environment in the age of global value chains. Outstanding efficiency, reliability, flexibility, and environmental compatibility represent the basic pillars of the gas engines in the output range from 400 kWel to 1,000 kWel. Their innovative drive is especially evident from the greatly reduced fuel costs, the extremely low lubricant consumption, and the digitized power plant control TPEM.

MWM Retrofit Kits for Hydrogen Operation

The gas engines of the TCG 3016 series can be used for operation with a hydrogen admixture of up to 25 vol%. With the MWM retrofit kit in two editions, operators of existing plants can retrofit their gas engines for operation with a hydrogen admixture of up to 20 vol% or 25 vol%.

Description – MWM Gas Engine TCG 3016

High Efficiency, Low Operating Costs

- Highest efficiency in its output class through unique combination of long maintenance intervals (80,000 operating hours for natural gas) and high efficiency (electrical efficiency up to 43.5 percent)

- The only gas engine on the market that combines efficiency with robustness to such a high degree

- Thanks to the optimized combustion, the electrical efficiency has been improved, and the vibration and stress that many components are exposed to has been reduced significantly.

Reduced Installation and Building Costs

- Smaller setup area than for comparable gensets thanks to compact design and integrated tanks for daily refilling

- Due to the flanged genset concept, the vibration decoupling takes place directly between the gas engine and the base frame, so that the setup costs are lower than for other gas engines.

- Reduced investment costs thanks to expanded product scope and new digital power plant control TPEM (Total Plant & Energy Management)

- Thanks to the optimized new combustion chamber geometry, higher mixture circuit temperatures reduce the dry cooler investment costs and ensure steadier combustion.

- Further benefits and technological improvements: Water-cooled turbo charger, flanged genset concept, optimized flow control of the fuel gas mix and optimized oil management of the gas engine

Optimized Lubricant Managament

- Greatly reduced oil consumption of 0.1 g/kWhel. Thus, the TCG 3016 gas engine boasts the lowest lubricant consumption in its class.

- Longer oil change intervals through innovative, leading-edge lubricant management

- Lubricant change intervals of up to 4,000 operating hours for natural gas and biogas (high and medium gas quality)*

- Up to 66 percent lower lubricant consumption compared to competitors

* Oil change must be performed after oil analysis

Performance Data – MWM Gas Engine TCG 3016

Natural Gas Applications, NOX ≤ 500 mg/Nm3 *

| TCG 3016 V08 P = Optimized for high electrical efficiency | TCG 3016 V12 P = Optimized for high electrical efficiency | TCG 3016 V16 P = Optimized for high electrical efficiency | |||||

|---|---|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 400 | 400 | 600 | 600 | 800 | 800 |

| Medium effective pressure | bar | 18.9 | 15.9 | 18.9 | 15.7 | 18.8 | 15.7 |

| Thermal output ± 8% | kW | 404 | 427 | 618 | 648 | 821 | 856 |

| Electrical efficiency | % | 43.1 | 42.2 | 43.3 | 42.4 | 43.5 | 42.6 |

| Thermal efficiency | % | 43.6 | 45.1 | 44.6 | 45.7 | 44.6 | 45.5 |

| Overall efficiency | % | 86.7 | 87.3 | 87.9 | 88.1 | 88.1 | 88.1 |

| Power to heat ratio** | 0.99 | 0.94 | 0.97 | 0.93 | 0.98 | 0.94 | |

* With 5% O2 and dry exhaust gas

** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Natural Gas Applications with 25 vol% Hydrogen (NOX ≤ 500 mg/Nm3* / 1.0 g/bhph*)

| TCG 3016 V08 P+ High Efficiency plus 25H2-Kit = Optimized for high electrical efficiency with 25 Vol.-% Hydrogen Kit | TCG 3016 V12 P+ High Efficiency plus 25H2-Kit = Optimized for high electrical efficiency with 25 Vol.-% Hydrogen Kit | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 400 | 400 | 600 | 600 |

| Thermal output ± 8% | kW | 403 | 423 | 614 | 637 |

| Electrical efficiency** | % | 42.8 | 41.9 | 43.0 | 42.4 |

| Thermal efficiency | % | 43.1 | 44.4 | 44.1 | 45.0 |

| Total efficiency | % | 85.9 | 86.3 | 87.1 | 87.4 |

| Power to heat ratio *** | 0.99 | 0.94 | 0.98 | 0.94 | |

| TCG 3016 V16 P+ High Efficiency plus 25H2-Kit = Optimized for high electrical efficiency with 25 Vol.-% Hydrogen Kit | TCG 3016 V16 S+ High Density plus 25H2-Kit = Increased power densitiy with 25 Vol.-% Hydrogen Kit | |||

|---|---|---|---|---|

| Ausführung | 50 Hz | 60 Hz | 50 Hz | |

| Electrical output | kW | 800 | 800 | 1000 |

| Thermal output ± 8% | kW | 816 | 848 | 1092 |

| Electrical efficiency** | % | 43.3 | 42.2 | 41.5 |

| Thermal efficiency | % | 44.2 | 45.1 | 45.7 |

| Total efficiency | % | 87.5 | 87.3 | 87.2 |

| Power to heat ratio *** | 0.98 | 0.94 | 0.91 | |

* for 5 % O2 and dry exhaust gas

** according to ISO 3046-1

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Biogas, Landfill Gas, and Sewage Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 3016 V08 X = Optimized for operation with all biogases | TCG 3016 V12 X = Optimized for operation with all biogases | TCG 3016 V16 X = Optimized for operation with all biogases | |||||

|---|---|---|---|---|---|---|---|

| Enginetype | 50 Hz | 60 Hz | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 400 | 400 | 600 | 600 | 800 | 800 |

| Medium effective pressure | bar | 18.9 | 15.8 | 18.9 | 15.7 | 18.8 | 15.7 |

| Thermal output ± 8% | kW | 394 | 414 | 599 | 627 | 791 | 827 |

| Electrical efficiency | % | 42.8 | 41.6 | 42.9 | 41.7 | 43.1 | 41.9 |

| Thermal efficiency | % | 42.2 | 43.1 | 42.8 | 43.6 | 42.6 | 43.3 |

| Overall efficiency | % | 85.0 | 84.7 | 85.7 | 85.3 | 85.7 | 85.2 |

| Power to heat ratio** | 1.01 | 0.97 | 1.00 | 0.96 | 1.01 | 0.97 | |

* With 5% O2 and dry exhaust gas

** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Specifications and Service Intervals – MWM Gas Engine TCG 3016

Dimensions and Weights

| TCG 3016 V08 | TCG 3016 V12 | TCG 3016 V16 | |||||

|---|---|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Bore / stroke | mm | 132/160 | 132/160 | 132/160 | 132/160 | 132/160 | 132/160 |

| Displacement | dm3 | 17.5 | 17.5 | 26.3 | 26.3 | 35.0 | 35.0 |

| Speed | min-1 | 1500 | 1800 | 1500 | 1800 | 1500 | 1800 |

| Mean piston speed | m/s | 8.0 | 9.6 | 8.0 | 9.6 | 8.0 | 9.6 |

| Length | mm | 3100 | 3100 | 3830 | 3830 | 4200 | 4200 |

| Width | mm | 1780 | 1780 | 1780 | 1780 | 1780 | 1780 |

| Height | mm | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Dry weight genset | kg | 5720 | 5720 | 7000 | 7000 | 8070 | 7700 |

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Service Intervals

| First service (check valve clearance) * | Spark plug change | Cylinder head inspection | General overhaul | |

|---|---|---|---|---|

| Natural gas | 2000 Oh *** | 4000 Oh | 40000 Oh ** | 80000 Oh |

| Purified biogas, landfill gas, and sewage gas | 2000 Oh *** | 4000 Oh | 32000 Oh ** | 64000 Oh |

| Unpurified biogas, landfill gas, and sewage gas | 1500 Oh | 3000 Oh | 24000 Oh ** | 48000 Oh |

* “after commissioning (E10)”

** “at the latest”

*** “gas quality High and Medium”

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Brochure – MWM Gas Engine TCG 3016

Further information on the TCG 3016 gas engines is available here.

MWM Gas Engine TCG 3016

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu: DE | EN | FR | ES | CN | NL

Download PDF: DE | EN | FR | ES | CN | NL

MWM Gas Engine TCG 3016 V16 S

Find out more about specifications, references as well as key selling points of the TCG 3016 V16 S: Outstanding price-performance ratio: Highest-in-class power density. High stress tolerance, optimum availability, and long useful life.

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu: DE | EN | FR | ES | TR | CN

Download PDF: DE | EN | FR | ES | TR | CN

MWM 25H2-Kit for TCG 3016

The TCG 3016 series now offers the possibility of natural gas operation with hydrogen admixture of up to 25 vol.% for both 50 Hz and 60 Hz. In addition to new engines, retrofit solutions are available for existing units in the field.

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu: EN | DE | ES | FR | NL | CN

Download PDF: EN | DE | ES | FR | NL | CN

Gas Engines & Products

MWM 25H2-Kits for hydrogen admixture for MWM gas engines

Existing plants of the TCG 3016 series can be upgraded with the MWM retrofit kit for operation with a hydrogen admixture of up to 20 vol% or up to 25 vol%.

360° MWM Container

360° View - MWM Container Cogeneration Plant with MWM Gas Engine TCG 3016

MWM Spare parts

With its logistics center in Lorsch, Germany, MWM guarantees efficient and reliable global spare-part supply.

MWM Service Tutorial Video #1

Do it the smart way

Basic Maintenance Tips

Episode 1: Spark Plug Replacement

MWM Service Tutorial Video #2

Do it the smart way

Basic Maintenance Tips

Episode 2: Valve Clearance Adjustment

TCG 3016: Power from Distributed Energy Generation for a Higher Quality of Life.

TCG 3016: Power from Distributed Energy Generation for a Higher Quality of Life.